당신은 주제를 찾고 있습니까 “ho scale steel mill layout – BRR Layout Tour: Scott Woods’ B\u0026LE/Union RR Steel Themed Layout“? 다음 카테고리의 웹사이트 https://ro.taphoamini.com 에서 귀하의 모든 질문에 답변해 드립니다: ro.taphoamini.com/wiki. 바로 아래에서 답을 찾을 수 있습니다. 작성자 Stephen Bennett 이(가) 작성한 기사에는 조회수 139,219회 및 좋아요 1,528개 개의 좋아요가 있습니다.

Table of Contents

ho scale steel mill layout 주제에 대한 동영상 보기

여기에서 이 주제에 대한 비디오를 시청하십시오. 주의 깊게 살펴보고 읽고 있는 내용에 대한 피드백을 제공하세요!

d여기에서 BRR Layout Tour: Scott Woods’ B\u0026LE/Union RR Steel Themed Layout – ho scale steel mill layout 주제에 대한 세부정보를 참조하세요

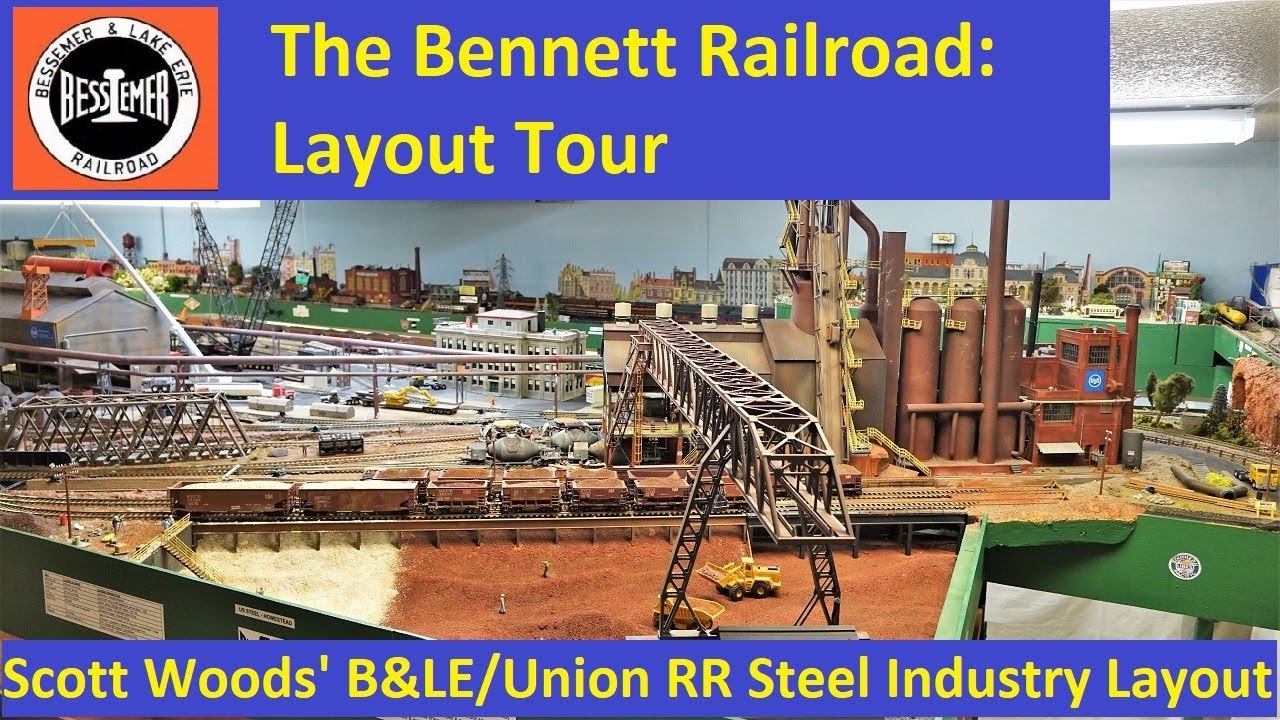

Welcome to a very special tour of Mr. Scott Woods’ Bessemer \u0026 Lake Erie, Union Railroad and Steel Industry themed HO scale layout. Scott’s layout is very extensive and detailed, and this video is long to enable covering most of it. Join us as Scott takes us on a walking tour of the layout. Along the way he explains the scenes and the actual operations of the steel industry items he is modeling- you are going to learn a lot about the steel industry on this tour.

Scott’s layout is a double deck arrangement, with the bottom level consisting mostly of the steel industry modeling. A helix connects the lower to upper level. The upper level consists mostly of B\u0026LE scenes and various other areas Scott wanted to include on his layout.

I did my best to capture the scenes and all the detail Scott has included, but there is no way one video is going to do justice to all Scott’s work. To say the least, this was a target rich environment!

As usual, the normal disclaimer about my breathing (was acting up a little that day) and I did try – TRY- to remember to use slow camera movements but please excuse any annoying camera work.

We wrap up the video with a photo collage showcasing Scott’s outstanding craftsmanship and attention to detail. I would like thank Scott for taking the time form his day to show his layout and for his very generous hospitality- he is a true gentlemen and an extremely talented modeler!

Thank you for watching. If you enjoyed, please Like, Share and if not a subscriber please Subscribe so you don’t miss any future updates, Product Information Videos, and other Model Railroading related videos!

ho scale steel mill layout 주제에 대한 자세한 내용은 여기를 참조하세요.

An HO Scale Multi-Deck Steel Mill Layout Plan

The Upper Deck houses the 4 Blast Furnaces, or Blast Furnace Row. There is no Highline, which will be part of the backdrop behind the furnaces.

Source: www.modelrailforum.com

Date Published: 10/29/2021

View: 6067

steel mill arrangement – Model Railroader – Trains.com

My layout was first built before Walthers reproduced the HO scale Ashland Iron & Steel complex of kits, but fortunately I had built a harbor …

Source: cs.trains.com

Date Published: 3/7/2022

View: 1679

주제와 관련된 이미지 ho scale steel mill layout

주제와 관련된 더 많은 사진을 참조하십시오 BRR Layout Tour: Scott Woods’ B\u0026LE/Union RR Steel Themed Layout. 댓글에서 더 많은 관련 이미지를 보거나 필요한 경우 더 많은 관련 기사를 볼 수 있습니다.

주제에 대한 기사 평가 ho scale steel mill layout

- Author: Stephen Bennett

- Views: 조회수 139,219회

- Likes: 좋아요 1,528개

- Date Published: 2019. 1. 5.

- Video Url link: https://www.youtube.com/watch?v=YgltMfmFZp4

steel mill arrangement

doctorwayne Member since

January 2004

January 2004 From: Canada, eh?

12,853 posts

Posted by doctorwayne on Monday, December 31, 2018 1:46 PM railandsail …My basic condensed version assumes the Rolling Mill assumes two roles,…accepts molten metal from the blast furnace, and turns it into basic shapes it ships out on the other end??… There is some misinformation in some of the earlier replies, and while I won’t address it specifically, perhaps I can shed a little more light on the subject. The hot metal from a blast furnace is iron, not steel. Over the years, there were several processes to turn iron into steel, but the most common involved either an open hearth furnace or a BOF (Basic Oxygen Furnace), the latter being the most common nowadays. Basically, it’s where additives are added to the molten iron to give it the properties needed for its end-use.

The plant where I worked produced steel in hundreds of different grades, most of them particular to specific customers. For example, we made steel for wheel rim to suit the differing specifications of Ford, GM, and Chrylser, and wheel spyder (the centre portion of a wheel, and with different specs than the wheel rim) for each, too….and there were several variations for each customer and each type. There were grades for nails, screws, re-bar, tire mesh, toe caps for safety boots, all sorts of grades for the various portions of automobiles, ships, and rail cars, armour plate, etc. etc.

Once the iron has become steel, it was usually poured into moulds to create ingots, although nowadays, it’s more efficient and less labour intensive to deliver it to a continuous caster. Ingots in our plant ranged in size from about 5 tons to 25 tons, and once poured and sufficiently cooled, needed to be either removed from their mould, or, more commonly, have the mould removed from them. This process occurred at the stripper building.

The still-hot ingots would be charged into a soaking pit, where they would be re-heated to a proper temperature for rolling – this varied for the type of steel, but was generally around 2350°F. Many grades required very specific heating practices, too: heating too quickly could cause the ingots to “wash” (the outer suface melting off the ingot, losing material and often detrimentally affect the steel’s properties). Once the steel was at the right temperature, it would be rolled into billets (the small ingots) or slabs (the larger ones…and in the mill in which I spent most of my working years). These would be cut to length on a large shear, then stacked and loaded onto rail cars, which delivered them to the next process.

I had a sequence of photos showing the process as it occurred within the slabbing mill, but loaned the photos to someone who “lost” them. Here’s a few, from another session, that I have left (having a camera within the plant was strictly forbidden, at threat of dismissal)… This locomotive (the plant had 24 GMD diesel switchers and 5 80 ton GE centre cabs) is pushing a string of ingot buggies into the stripper building, where a 600 ton crane will remove the moulds. The empty ingot buggies and the “goat” (made from an older ingot buggy, and at one time, with two couplers at one end, to accommodate two different styles of buggies with couplers at different heights) keep the locomotive at a safe distance from the hot ingots… In the background, to the right, is the BOF (in our plant, the general term for the building, but also the three BOF, usually pronounced “bawf”, furnaces within it.

The structure behind the hood of the loco, and extending well beyond, to the right, was #3 Open Hearth. In it were five open hearth furnaces, four of them with a capacity of about 300 tons each, and a fifth, rated for 500 tons per “heat” (batch of steel). The BOF furnaces were initially rated for about 100 tons each, but with technological improvement over the years, produced up to 140/150 tons, usually within 45 minutes to one hour. The open hearths generally produced at a rate of about one hour for each 100 tons of capacity. Behind the open hearth building and not visible, was # 2 Open Hearth, a smaller and older building with a number of small open hearth furnaces. These generally produced small batches of specialty grades, but it also closed as new processes emerged.

These were all furnished with hot metal from five blast furnaces. One was rather small (but much larger than the one represented by Walthers model), and was decommissioned a few years after I started working there, while three had a capacity of about 300 tons each, the fifth and largest, 500 tons. Here’s a locomotive spotting stripped ingots in the USM (Universal Slabbing Mill – where I worked for most of my years there). This is the soaking pit area, with the sides of the pits visible to the right…. The soaking pit portion alone of this mill was over a quarter mile long, with the rolling, hot scarfing (removal of surface defects), shearing, stamping, and piling areas extending to the right and behind from where the photo was taken. Part of one of the overhead pit cranes can be seen at the top of the photo – there were three in this mill. This photo (dark due to the brightness of the slabs) shows a pile of slabs cradled on the C-hooks of one of the two yard cranes. They’ll be placed on one of the barely-visible hi-riser cars in the background, then sent to the Conditioning Department for removal of defects befoire going for further processing…. There are more photos and info on the plant to be found HERE. That pretty-well covers the transition from iron ore to slabs or billets, which then went on to various finishing mills to be made into shapes for producing rod and wire (and nails, screws, and other fasteners), or finishing mills which rolled the slabs into sheet steel (mostly coils for automotive or appliance uses, but also a wide range of other products). It might also be coated (galvanising or other treatments).

Other grades were rolled into plates (heavy sheets) suitable for ship-building or military end-uses.

I don’t have a photo of a complete blast furnace (some are shown in the link) but here are a few shots of “E” Furnace, the largest of the five: The double-tracked skip bridge, which delivers the raw materials (ore, coke, and limestone) to the top of the furnace… …the stoves, which provide hot air for the blast… …and part of the casthouse…there’s part of a torpedo car visble at the bottom of the photo, while behind the piling-wall is the slag pit… I took the above photo because I was, at the time, trying to build a model of this furnace… The Company’s Technical Services Building supplied me with a fairly large stack of blueprints for the furnace, mostly general views, but enough to make the project possible. However, the furnace and casthouse alone occupied an area of almost 9 square feet, while the stockhouse, stoves, gas scrubbers, baghouses, and blower house would need even more room. While I did make some decent progress, I eventually came to realise that it was of too grand a scope to be practical, and abandonned it.

If you’re serious about modelling a steel plant or portion of it, Dean Freytag’s book would be a good volume to have.

And, as has been mentioned, there are lots of switching opportunities with a steel plant, including raw material-in (ore, coal, limestone, refractory materials, machinery, moulds and stools, skids for coil shipment in boxcars, etc.), product-out (coils, plates, fasteners, fencing, slag, chemicals from coke oven by-products), plus in plant movements from process to process. Nowadays, much is moved within the plant using rubber-tired vehicles but stuff coming in or going out is mostly by rail (truck, too, for shorter distances).

For example, we shipped treated finished cold-rolled coils (to a user unknown to me) in only 50′ plugdoor Union Pacific boxcars. These were on heavy duty wooden skids. While I mostly worked in only one area of a very large plant, I did have a few stints in other areas, so if you have any questions, I’d be pleased to answer any that I can. Wayne Reply

키워드에 대한 정보 ho scale steel mill layout

다음은 Bing에서 ho scale steel mill layout 주제에 대한 검색 결과입니다. 필요한 경우 더 읽을 수 있습니다.

이 기사는 인터넷의 다양한 출처에서 편집되었습니다. 이 기사가 유용했기를 바랍니다. 이 기사가 유용하다고 생각되면 공유하십시오. 매우 감사합니다!

사람들이 주제에 대해 자주 검색하는 키워드 BRR Layout Tour: Scott Woods’ B\u0026LE/Union RR Steel Themed Layout

- steel mill

- basic oxygen furnance

- union railroad

- rolling mill

- open hearth furnace

- b&le

- bessemer

- edgar thompson works

- how to model a steel mill

- conneaut ohio

- greenville pa

- walthers hulett unloader

- central wharf

- steel industry

- bessemer and lake erie

- layout tour

BRR #Layout #Tour: # #Scott #Woods’ #B\u0026LE/Union #RR #Steel #Themed #Layout

YouTube에서 ho scale steel mill layout 주제의 다른 동영상 보기

주제에 대한 기사를 시청해 주셔서 감사합니다 BRR Layout Tour: Scott Woods’ B\u0026LE/Union RR Steel Themed Layout | ho scale steel mill layout, 이 기사가 유용하다고 생각되면 공유하십시오, 매우 감사합니다.