당신은 주제를 찾고 있습니까 “api plan 32 – MECHANICAL SEAL API PLAN 32 | Rotating \u0026 Static Equipments“? 다음 카테고리의 웹사이트 https://ro.taphoamini.com 에서 귀하의 모든 질문에 답변해 드립니다: ro.taphoamini.com/wiki. 바로 아래에서 답을 찾을 수 있습니다. 작성자 Rotating and Static Equipments 이(가) 작성한 기사에는 조회수 3,501회 및 좋아요 20개 개의 좋아요가 있습니다.

Table of Contents

api plan 32 주제에 대한 동영상 보기

여기에서 이 주제에 대한 비디오를 시청하십시오. 주의 깊게 살펴보고 읽고 있는 내용에 대한 피드백을 제공하세요!

d여기에서 MECHANICAL SEAL API PLAN 32 | Rotating \u0026 Static Equipments – api plan 32 주제에 대한 세부정보를 참조하세요

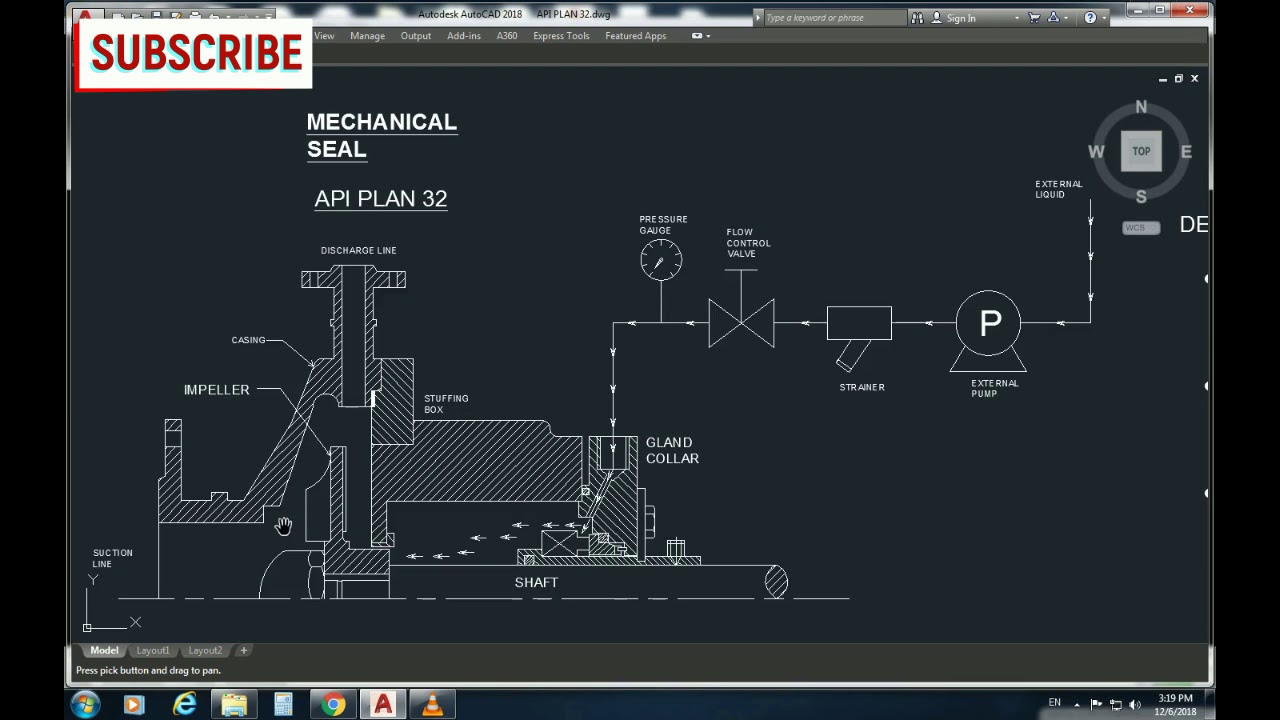

MECHANICAL SEAL PIPING API PLAN 32.

YOU CAN WATCH MORE VIDEOS IN MECHANICAL ROTATING EQUIPMENTS.

BELT DRIVE PULLEY ALIGNMENT STRAIGHT EDGE METHOD

https://youtu.be/TELnAX9DypM

RIM AND DOUBLE FACE DIAL ALIGNMENT FORMULA METHOD

https://youtu.be/6CwIQQCHQhA

REVERSE DIAL INDICATING GRAPHICAL METHOD ALIGNMENT

https://youtu.be/cSvvpwNEUoU

HOW TO FIND TYPES OF BEARING BY BEARING NUMBERS

https://youtu.be/bEtntvi8l3o

RIM AND FACE ALIGNMENT FORMULA METHOD

https://youtu.be/3qZK73sU5Wk

HOW TO FIX SHAFT ALIGNMENT SOFT FOOT

https://youtu.be/euJlKm2m2EU

api plan 32 주제에 대한 자세한 내용은 여기를 참조하세요.

API Plan 32 – AESSEAL

API Plan 32 · 1. Reduces flashing or air intrusion across seal faces by proving a positive flush. · 2. Maintains vapour pressure margin. · 3. Always proved at …

Source: www.aesseal.com

Date Published: 1/18/2021

View: 6844

API Plan 32 – EN – EagleBurgmann

API Plan 32 Injection of clean flu into the seal chamber from an external source. A From external source B To seal.

Source: www.eagleburgmann.com

Date Published: 11/9/2022

View: 2548

API Plan 32 – Flexaseal

API Plan 32 Clean flu is injected into the seal chamber from an external source. … into a quality seal flush through the use of other piping plans.

Source: www.flexaseal.com

Date Published: 7/28/2022

View: 8850

Plan 32 Technical specification | For wet single seals – Flopac

Plan 32 seal support systems are intended to improve the seal environment by bringing a controlled (cool) clean flush from an external source into the seal …

Source: flopac.com

Date Published: 4/28/2022

View: 8602

API Plan 32 – ESS Pump & Seal

API Plan 32. FLOWTRUE – Flow Meter. The AESSEAL FLOWTRUE® is a robust and adjustable flow meter that controls the amount of water flowing to the mechanical …

Source: www.ess4solutions.com

Date Published: 10/6/2022

View: 5608

What is API plan 32? – Interview Area

API Plan 32 delivers a clean flush flu into the seal chamber from an external source. Typically used with a close-clearance throat bushing, this arrangement …

Source: www.interviewarea.com

Date Published: 10/15/2021

View: 4317

주제와 관련된 이미지 api plan 32

주제와 관련된 더 많은 사진을 참조하십시오 MECHANICAL SEAL API PLAN 32 | Rotating \u0026 Static Equipments. 댓글에서 더 많은 관련 이미지를 보거나 필요한 경우 더 많은 관련 기사를 볼 수 있습니다.

주제에 대한 기사 평가 api plan 32

- Author: Rotating and Static Equipments

- Views: 조회수 3,501회

- Likes: 좋아요 20개

- Date Published: 2018. 12. 11.

- Video Url link: https://www.youtube.com/watch?v=sFVbQLDBGaE

API Plan 32

Description

Injection of clean or cool liquid from external source into the seal chamber.

Features

1. Reduces flashing or air intrusion across seal faces by providing a positive flush.

2. Maintains vapour pressure margin.

3. Always provided at a pressure greater than seal chamber pressure.

4. If maintained properly the best of all single seal plans (subject to acceptance of contamination).

Use

1. Dirty or contaminated fluids.

2. High temperature applications.

3. Polymerizing and oxidizing fluids.

4. Media with poor lubrication properties.

Caution

1. External source should be continuous and reliable at all times, even during start up and shut down.

2. Flush fluid must be compatible with process fluid due to product contamination.

3. Product degradation can occur.

4. Ensure use with close clearance throat bushing to maintain pressure in stuffing box and control the rate of contamination of pumped media.

5. Careful selection of flush fluid required to ensure that it does not vaporize on entering the seal chamber.

6. Fluid expenditure of Plan 32 may be as expensive as one or more seals per year.

API Plan 32

Configurations

1CW-FL, 1CW-FX, 2CW-CW, 2CW-CS, 3CW-FB, 3CW-BB, 3CW-FF

3NC-FB*, 3NC-BB*, 3NC-FF*

* Remark: The configurations listed for each individual piping plan are to be understood as recommendations including possible utilizations which may also be applied.

API Plan 32

Clean fluid is injected into the seal chamber from an external source.

Description

Satisfactory plan for use in achieving a clean and cool environment. Requires the injection of clean fluid from an external source.

Application Notes

For use in services containing solids or contaminants, in which a cleaner and cooler external flush will improve the seal environment.

External flush source must be continuous and reliable.

Pressure of the external flush should always be at least 25 psi [1.7 bar] above the seal chamber pressure.

Throat bushing is required to maintain an elevated pressure in the seal chamber, isolate it from the pumped media, and reduce flush fluid consumption.

Provides the seal with a cool, clean lubricating fluid when the product cannot be conditioned into a quality seal flush through the use of other piping plans.

Flush fluid must be compatible with the product because product dilution will occur.

Pros:

Improved cooling, lubricity and cleanliness of process fluids

Cons:

Plan 32 Technical specification

A Plan 32 injects a (cool) clean flush liquid at elevated pressure into the seal chamber from where it will flow into the process. To maintain an elevated pressure and to avoid all too excessive losses of flush liquid the seal chamber should best be isolated from the process by a close-clearance throat bushing.

The injected flush at elevated pressure will prevent the contaminants of the pumped liquid to approach the (inboard) seal provided it is continuous and sufficient.

A properly designed Plan 32 operates self-reliant provided the continuous and sufficient supply of flush liquid is ensured. That will require a highly reliable ‘external source’. Should such external source not be readily available, kindly address Flopac for our range of well-engineered Seal Flush Injection units.

API Plan 32 — ESS Pump & Seal

API Plan 32

FLOWTRUE – Flow Meter

The AESSEAL FLOWTRUE® is a robust and adjustable flow meter that controls the amount of water flowing to the mechanical seal for cooling purposes. The unique and advanced FLOWTRUE® design means that of all the flow meters available it is the least likely to clog. This is due to large internal clearances within the design. There are three models of the FLOWTRUE® available, which enables the product to be used on packing applications, single seals and double mechanical seals.

Features:

What is API plan 32?

What is API plan 32?

API Plan 32 delivers a clean flush fluid into the seal chamber from an external source. Typically used with a close-clearance throat bushing, this arrangement can be used to ensure a higher pressure in the seal chamber.

What are API plans?

What is API plan 52?

What is API plan 53?

What is API plan 23?

MECHANICAL SEAL PLAN#32 EXPLAIN IN HINDI API682

What is API plan 11?

What is pumping ring in mechanical seal?

What is API plan 54?

What is the difference between Plan 53A and 53B?

What is buffer fluid and barrier fluid?

Why seal flushing is required?

How does 53c plan work?

How many types of mechanical seals are there?

What is API standard for pumps?

What are API plan for seal?

What is API flushing plan?

What is a seal in engineering?

What is double mechanical seal?

What is seal chamber pressure?

Why seal is used in pump?

How do I choose a mechanical seal plan?

When selecting the seal’s material of construction, be sure to consider the following characterstics of the material:

Temperature constraints. Chemical resistance properties. Flexibility. Wear resistance. Thermal expansion and conductivity properties.

How does pump seal flush work?

What is a Type 21 mechanical seal?

What are the two main parts of a mechanical seal?

What are the three basic parts of a mechanical seal?

These are standardized flushing piping arrangements that are widely used in the industry. Customer specific variants of these plans are possible. API Piping plans help to ensure good conditions for mechanical seal operation as well as improving safety and pump reliability.API Seal Plan 52 utilizes a reservoir and circulates an unpressurized buffer fluid between the inboard and outboard seals. To provide positive circulation through the support system and into the seal, a pumping ring is employed.API Plan 53B circulates a pressurized barrier fluid between the inboard and outboard seals. The source of pressurization is a bladder accumulator. Plan 53B has the advantage of not allowing gas absorption into the barrier fluid which may allow for operation at higher pressures than Plan 53A.API Plan 23 utilizes a circulation device, typically a pumping ring, to route the fluid from the seal chamber through a cooler before returning the cooled fluid to the seal chamber. A throat bushing isolates the cooled seal chamber flush fluid from the hotter pumped liquid.API Plan 11 recirculates flow from a high‐pressure section of the pump, typically the discharge piping, through a flow control orifice to the seal. Plan 11 is the default flush plan for most pumps. API Plan 11.A pumping ring in the seal circulates the buffer fluid (pressure less than seal chamber) to the reservoir. This flush plan is very common in applications with VOCs (Volatile Organic Compounds), however if not set up similar to the schematic in Figure 8.3.API Plan 54 is a custom engineered system that delivers a pressurized barrier fluid to the seal chamber. The barrier liquid is circulated to and from the seal chamber via a pump located on an external reservoir. This fluid is maintained at a pressure greater than that found in the seal chamber.The major difference in the plans is that Plan 53A uses an external reservoir, while Plans 53B and 53C run within a closed loop system with a make-up system piped to it for replenishment of the barrier fluid.When this fluid is unpressurized, it forms a buffer between the pumped fluid and atmosphere and is commonly referred to as a buffer fluid. When pressurized, it forms a barrier between the pumped fluid and atmosphere and is known as a barrier fluid.The purpose of the maintenance procedure is to flush any debris from between the seal faces. That debris may have come from particulates in the process fluid, corrosion from aging piping, or metal from an abraded pump volute or impeller.Barrier fluid system pressurized by a piston accumulator supplying clean liquid for an arrangement 3 pressurized dual seal. The barrier pressure is generated from the seal chamber pressure. The system is self-energizing and reacts to fluctuations in the seal chamber fluid pressure.8 Types of Component Mechanical Seals.API 610 is the API standard about centrifugal pumps and is primarily intended for use in the petroleum, natural gas and chemical industries. Although the 1st through 7th Editions of API 610 included specifications for mechanical seals, beginning with the 8th Edition, API 610 defers to API 682 for seal specifications.Detailed API seal piping plans ensure minimal seal face wear by maintaining the optimal seal chamber environment. Since they were first formulated, seal piping plans have been maintained and remodeled by the American Petroleum Institute (API). Current plans are based on API 682 and are sorted numerically.Description: Process side API seal flush plans use a single mechanical seal to prevent pump (process) fluid from leaking. In this arrangement, the process fluid is the lubricant. It provides a thin film between the seal faces to reduce friction and absorb heat.A mechanical seal is a device that helps join systems or mechanisms together by preventing leakage (e.g. in a pumping system), containing pressure, or excluding contamination. The effectiveness of a seal is dependent on adhesion in the case of sealants and compression in the case of gaskets.A double mechanical seal is a type of mechanical seal with two primary seals or sets of faces, it can operate in various arrangements with a) a barrier (containment) between the sets of faces or b) a buffer (mixing).The seal chamber pressure is a function of wear ring clearance as well as size and location of the balance holes. Two Stage Horizontal Pumps. Impeller arrangement can have two. configurations: 1.)Mechanical seals are critical components in centrifugal pump systems. These devices preserve the integrity of the pump systems by preventing fluid leaks and keeping contaminants out. Mechanical seal systems are used on various seal designs to detect leakage, control the seal environment and lubricate secondary seals.This method consists of a minimal flow of a clean, relatively cool liquid (usually water) from an external source injected into the seal gland flush connection at a pressure higher than the pump seal chamber pressure. The external flushing liquid flows past the seal and into the pump, mixing with the pumped fluid.General-duty Elastomer Bellows Shaft SealThe Type 21 is ideal for use in centrifugal, rotary and turbine pumps, compressors, chillers and other rotary shaft equipment. It is also commonly used by the wastewater and water systems industries for applications such as waste treatment, potable water and HVAC.A stationary ring (usually the stationary seat) arranged in the stationary part (casing) Secondary seal (usually O-ring) between these parts.Typically, a mechanical seal contains:Secondary static seals, V-rings, O-rings or wedges. Static seal or stationary component.

키워드에 대한 정보 api plan 32

다음은 Bing에서 api plan 32 주제에 대한 검색 결과입니다. 필요한 경우 더 읽을 수 있습니다.

이 기사는 인터넷의 다양한 출처에서 편집되었습니다. 이 기사가 유용했기를 바랍니다. 이 기사가 유용하다고 생각되면 공유하십시오. 매우 감사합니다!

사람들이 주제에 대해 자주 검색하는 키워드 MECHANICAL SEAL API PLAN 32 | Rotating \u0026 Static Equipments

- MECHANICAL SEAL API PLAN 32

- API

- API Plan 32

- 32

- Rotating & Static Equipments

MECHANICAL #SEAL #API #PLAN #32 #| #Rotating #\u0026 #Static #Equipments

YouTube에서 api plan 32 주제의 다른 동영상 보기

주제에 대한 기사를 시청해 주셔서 감사합니다 MECHANICAL SEAL API PLAN 32 | Rotating \u0026 Static Equipments | api plan 32, 이 기사가 유용하다고 생각되면 공유하십시오, 매우 감사합니다.